SPM MACHINES

• Pharma & Surgical Medical Equipments

• CRC Wad Cap Machines

• Syringe Assembly Machines

• Drip Chamber Assembly

• Scalp Vein Assembly Mc

• IV wing Assembly Mc

• High Speed Tube Cutting Mc

• Tip Forming / Flaring Mc

• Hub Needle Assmb. MC

• Flash Cap Ass. Machines

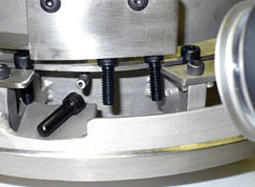

CRC Inner Cap & Wad Cap Insertion Machine - HA Model

Hindustan Automation manufactures and supplies a wide range of wad insertion machine which is extensively used to be fixed under plastic cap of any bottle specially used in cosmetic packaging industry. Some of the models we offer have peripheral equipment (HA Hopper, HC Elevator & HA Bowl Feeder) integrated to the main lining system offering you a fully compact machine built onto a mobile platform. These are well suited to insert the wads into plastic caps that saves manpower and precious time of our esteemed customers. These are rigorously examined by our in-house experts to ensure its flawless functioning.

As a leading wad insertion machine manufacturer, we are offering an extensive range of products at affordable prices. The machine is capable of inserting liners or wads into metal and plastic closure.

- pre cut liners

- punching from reel fed tape

- universal tooling for both of the above

Speed: 60-200caps/min

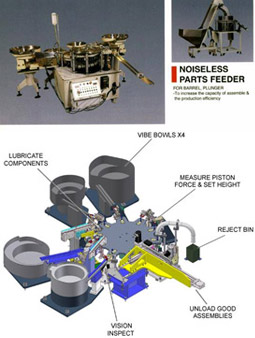

Disposable Syringe Assembly Automation - HA Model :

(MULTI-USE) H-SPM provides noiseless part feeder & Auto assembly of Disposable Syringe. Syringe Assembly Unit with Electronic Control Circuit

Configuration

HA Parts Feeder for Barrels , HA Parts Feeder for Cap With Needle,

HA Parts Feeder for Gaskets , HA Parts Feeder for Plunger

Production Capacity :

7,000 pcs ~ 8,500 pcs(multi-use) , ..13,000 pcs ~ 18,000 pcs (mono-use) , Air Consumption : 7 kg/?, 600 L/MIN, Electric Power : AC220V Electric Power Consumption : 1 kw , Machine Dimension : 800(W)x1300(D)x1200(H) mmx1500 kg, System

Automatic Needle Assembly Machines - HA Model :

Our organization is counted among the most distinguished manufacturers and suppliers of Automatic Needle Assembly Machine

Other information

Production Capacity: 1320 - 1500 pcs per hour

Delivery Time: 15 -16 weeks

The machines offered by us are designed and fabricated under the supervision of professionals. Assembled needles are unloaded automatically on the stands and the output of machine is approx 1400 pcs per hour with approx 99% needle orientation along with plus/minus 0. 1 mm length variation (which is very precise needle length)

Technical specifications:

PLC & sensors Mitsubishi, omron and hmi pro face/delta.

Out put of the machine is between 22~25 pcs. Per minute or 1320 ~1500 pcs per hour.

Pneumatics used in this machine are festo/smc.

Needle orientation approx 99%.

For long life of grippers, we are using indian/custom make.

Length variation plus/minus approx 0.1 mm

Luer Lock & Flash Back Chamber Machines - HA Model :

Owing to the sophisticated manufacturing facility, we have been able to offer Automatic Luer Lock and Flash Back Chamber Assembly Machine. The offered machines are fabricated under the strict surveillance of our professionals in accordance with the international standards. These machines are widely used to assemble two parts (luer lock & flash back chamber). Moreover, our offered machines have two tracks as well as four tracks in order to meet the requirements of customers. Both parts are assembled with help of pick & place unit and discharged through chute. Further, our machines have the capability of gives output from 4,500 pcs. to 9,000 pcs. per hour depending upon the nos. of tracks.

Required man power: 1 Person

Production Capacity: The Output of the 2 Tracks Machine is 4500 Pieces Per Hour and the Output of the 4 Tracks Machine.

Technical specifications:

Machine frame size 850* 1250 * 800 mm

PLC Mitsubishi/OMRON make & sensors imported from Japan or German, For 2 tracks 2 nos and for 4 tracks 4 nos of separate motors are used to feed the FBC in Pin feeders, For pin feeders 25 watt ORIENTAL geared motors with AC drives are used Pneumatics of FESTO/SMC make are used Output of the machine is between 4,500 ~ 9,000 pcs per hour depending upon the tracks selected

Body Assembly Machines - HA Model :

Innovation is our forte and we strive to design and develop Body Assembly Machine. These are designed on two tracks and double station and two stations are fixed on one table. Further. three components are assembled at our machines such as slip ring, cup formed teflon & wing housing/body. Cutting at wing assembly is clear and straight in length then the customers get very good tipping quality subject to the die quality.

Technical specification:-

PLC Of Mitsubishi, Keyence, Omron, Delta make

Output of single station is between 600~650 pieces per hour/station. It means 1200~1300 pcs per hour

MS Plate with Electro Less Plating (Very Long Life) machine table size 700* 650 * 800 mm

Maximum length variation plus/minus 0.3mm

Power consumption 0.25 Kw

Pneumatics used FESTO/SMC/CKD Make

Air consumption 3.0 cfm at 6.0 bars

Required manpower is 02

Output: Approx 600~650 pieces per hour/station that means 1200~1300 pieces per hour

Tip Forming Machines - HA Model :

We are engaged in manufacturing wide range of Tip Forming Machine. These are developed using high grade machines and equipment following the set industry standards and quality norms. These are widely acclaimed in the market for their low maintenance, easy installation, high performance and durability.

Technical Specifications of the products are:

PLC of Delta, Omron or Mitsubishi make

Touch screen monochrome Delta or Proface

Air consumption 3.0 cfm per minute

Chilled water consumption 3.0 liters per minute

Manpower Requirement=01, Power consumption 2 KW, Output approx 750 pieces per hour

Table Top Plate, MS Plate with Electro Less Plating (Very Long Life) (750 * 700 * 12 mm)

Machine Frame manufactured from Imported Aluminum Extruded Profiles, Induction Heating Generator Indian or Taiwan make Pneumatics used FESTO/ SMC/ CKD make, Machine Table size 750* 700*700 mm, Exair cold air gun for proper die cooling.

Automatic SiliconTube Cutting Machines - HA Model :

![]()

Owing to the hard work of our professionals, we are capable of offering Automatic Silicon Tube Cutting Machine. These are designed with utmost perfection by our engineers using advanced machines and equipment. Our raw material for the product are sourced from some of the most reliable vendors in the industry. The machine is very compact with a table top design and comprises a output capacity of 4000 to 4200 pieces per hour.

Technical Specification:

• Fully Automatic

• 25 watt variable speed geared motor

• Cutting Length as per Clients requirements, otherwise 9 mm ± 0.2mm

Other Information:

• Production Capacity: 4000 -4200 pcs per hour

Automotive Special Purpose Machines:

• Pointer Bobbin Assembly Machines• Valve Piston Assembly Machines

• Leak Testing Machines

• Flow Rate Test Machines

• Speedo Meter Pointer Assembly Machines

• Performance Checking Machine

Automated Test Machines - HA Model:

It is vitally important to our customers that products they manufacture are of good quality. Often it is also necessary for our customers to demonstrate to their customers that robust quality checking procedures are in place. To complement our process automation machines we also produce test machines. They may be stand-alone units or incorporated into assembly machines and may store test data locally or upload it to a customer's host system, according to needs.

In process and post process tests performed by HA Model machines are diverse, including:

1) Force, Torque, Distance and Angle Measurement.

2) Pressure, Flow and Leak Testing.

3) Electrical Testing.

4) Functional and Endurance Testing.

5) Machine vision checks (product variant, completeness, quantity, etc.

Vision Inspection System - HA Model :

HA Model offers & integrate a wide range of inspection systems, including contact and non-contact inspection systems. Our systems can verify marking on a component, verify the presence of the components, verify height and depth and flatness and much more.

We utilize high speed vision, laser inspection, depth and height sensors, gage plate inspection and other components in our automated inspection systems

Applications where vision systems are useful include:

• Parts that must be oriented or sorted based on internal features.

• Parts with different colors.

• Sorting for quality issues such as missing or malformed threads.

• High-speed sorting.

• General Features:

• Smart Camera Technology

• Component Feeding Flexibility

• One Touch Component Programming

• Contour Scanning or Full Image Inspection

Cup Forming Machines - HA Model:

Technical specifications:

• Machine table size 1000 * 850 * 800 mm

• Table top plate, ms plate with electro less plating (very long life) (1000 * 850 * 12 mm)

• Pneumatics used of Festo/ SMC/ CKD make

• Reed switches of FESTO/SMC/CKD and sensors of sick optics/Omron

• Machine frame manufactured from imported aluminum extruded profiles

• 6 Tracks & souble station

• PLC Mitsubishi/Omron/Delta 24VDC & HMI Pro face/delta

• Output: Approx 2250~2500 pieces per hour per station, hence capacity is 4500~5000 pieces per hour

• Air Consumption 3.5 cfm per minute at 5.0 bars

• Chilled water consumption 3 liters per minute

• Cup forming pins are used highly polished & hard chrome plated

• Power consumption 2.5 Kw

• Manpower requirement is 01

Hi-Tech Special Purpose Machines

:

• Weather Shed Assmb. Machines

• Glass Coating Machines

• Capacitor Cold Pressing Machines

• Bi-Metal Tapping Machines

• U-Clamp Machines

• Riveting Machines

Value Added Products

:

Robotic Integrated System - HA Model

HA Model builds and integrates robotic systems for your precise and high-speed applications. We offer robotic systems (2,3,4 axis) made from combinations of linear slides and rotary actuators to handle part placement, stacking, machining, inspection, welding, and much more.

Industrial robots, especially six-axis robots, provide flexibility and dexterity which is unsurpassable for some operations. The true worth of a robot is realized only when it is integrated with our HA feeding equipment and tooling in a production cell.

At HA Model we have experience in integrating robots from a number of different manufacturers in a variety of applications which includes installation & programming support for application such as:

• Loading / unloading assembly and test machines

• Applying adhesives, sealants and surface preparation agents.

• Handling products to / from packaging

• Assembly operations.

• Laser welding.

• Furnance Loading & Unloading

• Articulated Part Placement & Positioning

• Articulated Part Positioning

• Inspection & Verification

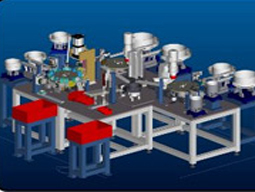

Assembly Line Automation - HA Model

:

Inspection can be integrated on the machines. Components can be secured by the application of adhesives, welding, ultrasonic or induction sealing. We can also incorporate slitting, drilling, tapping or screw stations.

Such SPM Includes:

1) Lipstick Assembly Machine

2) Writing Instrument Assembly Machine

Single Source Responsibility:

We provide a complete solution by integrating our proprietary feeder bowls to position the parts to be assembled, along with a vision system that qualifies acceptable & defective assembled parts before being packed. In this way, we take full responsibility to deliver a fully tested and functional turnkey system that feeds, positions, assemble, inspect and pack the final marketable products.

We have successfully installed assembly lines, on pan India basis, for the Plastics, Metals, Medical Devices, Writing Instruments and Cosmetics & Personal Care industries. Some examples include powder & eye shadow compacts, lipsticks, mascaras, lip-gloss tubes.