HINDUSTAN AUTOMATION

• Vibratory Bowl Feeders

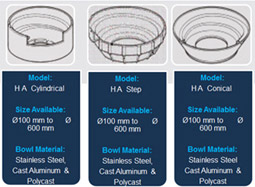

HA BOWL UNITS: Bowls have distinct tooling features & the most important factors to consider when selecting the best type of bowl for your particular applications is by determining the component size, its configuration

HA DRIVE SYSTEM: HA drive units are correctly engineered to give stable performance at high speed with minimum maintenance.

Totally Encapsulated Type coils with adequate power for particular models, are used. An easily removable Safety Guard / Cover giving easy access is provided for the Drive Unit.

HA 300 Cylindrical Model

HA 300 Step Model

HA 400 Connical Model

HA 400 Step Model Integrated with HA LFE 170 Linear Model

HA 500 Connical Model

BOWL SELECTION:

The Bowls have many distinct tooling features & the most important factors to consider when selecting the best type of bowl for your particular applications is by determining the component size, its configuration

Linear Feeders / In Line :

Linear Feeders :

HA in line/linear feeders can be installed in all sorts of environment. We recommend linear feeders with replaceable guides for different sizes of the components. This will again give you trouble free feed rate.

Track Surface Finished :

S.S. Surface Polished / Hard Chrome Plating. They are best suited for high-speed conveyance of small & thin precision pharmaceutical, automobile, glass, electronic & battery parts. Models are available from light duty to heavy-duty type depending upon the component size, thickness,& material type.

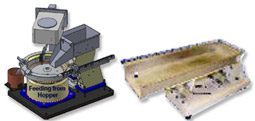

Stock Feeders / Hoppers :

Hoppers / Stock Feeders :• HA eliminate the problems associated with vibratory bowls being overfilled.

• They provide a consistent supply of parts as well as reduce the need for frequent operator attention to parts level in the bowl.

• The reduce attention requirements & allow operator to focus on more productive functions of a production line

Stepper Feeders / Elevators

:

HA Elevators :

Most production, assembly, warehousing & storage operations have a requirement for materials handling equipment. They are ideally suited to solving handling problems as a complete solution for feeding components.

HA Stepper Feeders :

Specializes in the design & supply of Billets.

We suggest Stepper Feeder, for speeding the flow of billets & for economic processing in the heavy materials handling industry.

Conveyors

:

HA Conveyors :

HA manufactures various types of conveyors i.e. Belt conveyors, Chain conveyors, Slat Conveyors, Bucket Elevator, Screw Conveyors, Snake Type Conveyors & Gravity Roller Type Conveyors.

They are designed as per size & weight of the job to be conveyed, distance to be conveyed, volume of material to be conveyed in Kg/hr & inclination angle (if any).

HA Idlers / Roller Conveyors :

We suggest Powerised Roller Conveyor & Idler Roller Conveyor for speeding the flow of goods & for economic processing in the heavy materials handling industry.

A lifting & tipping unit can be used if required for a load bearing capacity of 1 to 2 tons.

SPM / Escapement & Placement Mechanism

:

HA Special Purpose Machines :

HA designs & manufacture assembly equipment to suit an individual client’s product requirements. The equipments produced by HA can also incorporate where required inspection & test facilities to ensure that the assembled & tested product has been validated at various stages during the production process thereby reducing end of the line reject rates & production costs.

We have successfully installed following m/c’s: -

Air Jet Drilling SPM’s

Rivet Assembly Machine

Bolt Feeding System

Note : Details of these machines can be shared on special request by client

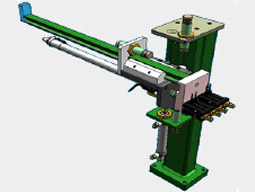

HA Escapement & Placement Mechanism:

HA has complete part escapement design & build capabilities in-house. Escapements are used to accurately separate & position parts for pick up or delivery by a robotic arm or pick & place system